that should work well. There should not really be any significant interference.

Welcome fellow biohacker! Based on your name, you’re from my hometown (I now have a practice and live in Niagara)

Very nice to hear from you Dr. Friesen. Yes, well pretty much—I’m from nearby London and did also live in Toronto. I still travel to Ontario occasionally as I have some farmland to inspect in Chatham-Kent. I was planning to visit now but the border is closed so I will probably wait a year.

Be well!

Robert

Very cool. Drop me a line if you ever want to discuss biohacking

what an excellent design improvement… what do you think @Bob of this suggestion for product improvement?

well… the design for most of the system has converged to a point where almost any change will get about 50% of people who like it, and 50% who do not.

In this case:

–about 50% will say they like more durable coils, but…

–about 50% will say it is too bulky (or have some other complaint)

So… my strategy is to gravitate to a design that is simple, inexpensive, and easily modified by the user as they see fit. That means that the current design is just fine for people who want more robustness at the expense of added bulkiness.

For the others, they will not make this change.

But, by NOT changing the design for every suggestion there is one way in which I can make everyone relatively happy: no need to increase price to defray $50,000 of tooling and production costs with every change.

So, people can modify, or not, as they see fit. That is a key aspect of ICES-PEMF products in general.

Just adding that I continued to have problems, BUT we “splinted” the coil in a similar way, both with a tongue depressor and then electrical tape.

And I have since discovered that I don’t need to wear them all night anymore, so that fixed my problem.

i’m noticing that the plastic the coil wires use are a bit brittle. i’ve already had 2 pairs break at the end of the coil. fortunately, they still work, so i wrapped the point where coil meets wire to hopefully protect that connection point. i use them mostly for sleeping on and do have them taped/stacked.

have you noticed @Bob feedback about coils being brittle/breaking where coil and wire meet?

Yes, we keep trying to make improvements to the coil manufacturing process. Believe it or not, they have really improved a lot in the last few years. By far, the most difficult things to get right are:

1- Batteries and connections

2- Coils and connections.

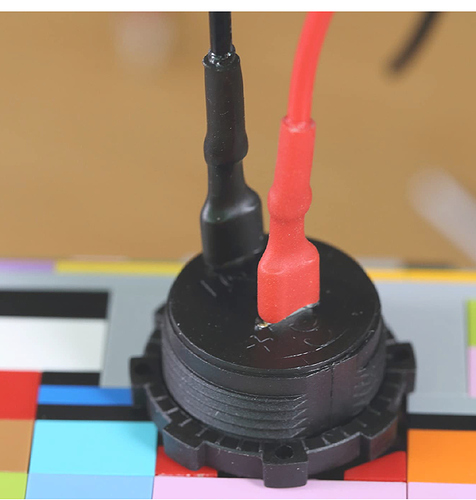

currently have electrical tape but that didn’t last a night… then i saw shrink tubing… what gauge (@Bob) should i get? i likely will cut tube and double up, then heat shrink… like this

The only problem with using heat shrink tubing is the fact that you can’t slip it over the coil or the plug in its uncontracted state. I don’t see a way to make this work.

Based on the failure analysis I have done, the coil failure is due to the loss of adhesion between the coil rubber (TPR, grey) and the black vinyl insulation of the wire cable. When these slide, it places torsional and tension stress on the conductive wires inside. So, a stress-relief type of fix does not work well. What is really needed is a strong but flexible bond between the rubber and the vinyl.

I have done a lot of experiments and my conclusion is that a bonding agent such as flexible crazy glue will work. I have been testing it, and it works very well. Most types of crazy glue are too brittle and will eventually crack at the interface, but two types of elastic crazy glue have done very well in my testing - both are Insta-flex glues by Bob Smith Industries:

https://www.amazon.com/gp/product/B002N507IA/ref=ox_sc_saved_title_5?smid=A1YXRRW7DIGLMH&psc=1

and

https://www.amazon.com/gp/product/B002N4UD3U/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1

The one with the blue cap is very watery but will easily flow into the tiniest gap. It also runs all over the place and invariably gets on your fingers (dang-it!). The one with the pink cap is more like a gel, but it is easier to control than the watery one.

Both of these create an excellent, flexible bond between the grey rubber coil and the black vinyl cable insulation, and if you apply them carefully into the narrow gap between these (it helps to bend the wire to the side when applying to open the gap for the glue), the resulting coils are much more durable. You need to let the bond set fully, generally this means letting it set overnight.

You can then add things like electrical tape if you want to, as long as you also apply a small amount of this glue to it to keep it in place. But I don’t think that is necessary. The strong and flexible bond between the coil and cable is the most important thing.

If you choose to do this, you need to be very careful because any form of this type of glue is dangerous to skin and eyes.

Hi Bob, one of my coils (12") has a connection issue and rather than throw it out I want to modify and extend it. Would this amazon wire work?

yes, that wire would work fine, but this (silicone) might be a bit better:

Thanks. As much as I want just get news ones. I do have 2 sets of coils. The next order of coils is with a side of C5!

Experiment is complete, status = FAILURE! Please read details at the end of this post.

What about this, I’m planning on lining the inside with saran wrap, then 30 min epoxy to dry overnight.

UPDATE, since my new coils are arriving in the mail today, I decided to try this experimental coil life extension technique:

FYI, My original M1 coils lasted me 3+ years. Admittedly, I didn’t use the M1 a lot, but its’ on the top of my list since discovering it does help my sleep (even when its near my gut). I did experience my first coil failure a few days ago, which is why I am here. I will probably wrap the base of the coil in electrical tape after the epoxy dries.

I am now having some doubts about this actually working, so I suggest NO ONE try this until I can confirm it works or not!

Final Update: After the epoxy set, I realized the epoxy cured around the wire, but the wire was easily able to rotate around the base of the coil, possibly shortening the life even more. So, I carefully hammered out the dried epoxy, fortunately the coil is still working.

I’m wondering if a more flexible wire could be used to attach the coil to the M1? Would it be worth it to splice the wire at the base of the coil, leave just enough length to attach a new M1 connector? If we used a thin multistrand cable, would the signal get degraded?

Reminds me of Elon Musk talking about the development cycle of a reusable rocket where he cuts away things but has to build back things through trial and error mixed with engineering insights that then have to be proved out.

This reminds me of when laptop powerbricks need to be replaced because joints get flexed too much even thought that’s kind of built into the logic of having external wiring that is expected to move.

that durable sticky tape… Teflon tape(?) works well for me so far… it’s just how you wrap it that matters.

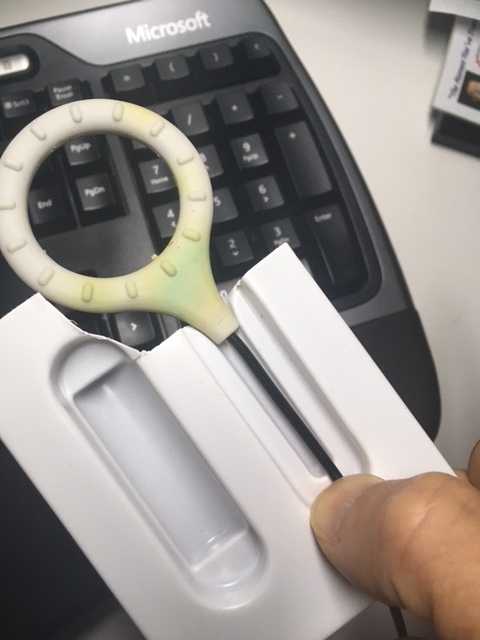

Have you tries Sugru? It’s used often for Lightning cables about to fail, and for a while I would fix then before I started to use them, until I started using better quality cables. Even they fail eventually.

But can Sugru be used in one or more scenarios by users?

things like that can help, but they will make the coils a bit more bulky.